Kablolar

Kablolar, elektrik akımını iletmek veya veri transferi yapmak için kullanılan tellerden oluşan bir yapıdır. Kablo seçimi, iletişim ve enerji ihtiyaçlarını karşılamak için önemli bir faktördür.

Spiral Kablolar

Spiral Kablolar, esnek yapısı sayesinde hareketli sistemlerde kullanıma uygun ve düzenli bir kablo yönetimi sağlar. Bu kablolar, özellikle endüstriyel ve otomotiv sektörlerinde yaygın olarak tercih edilir.

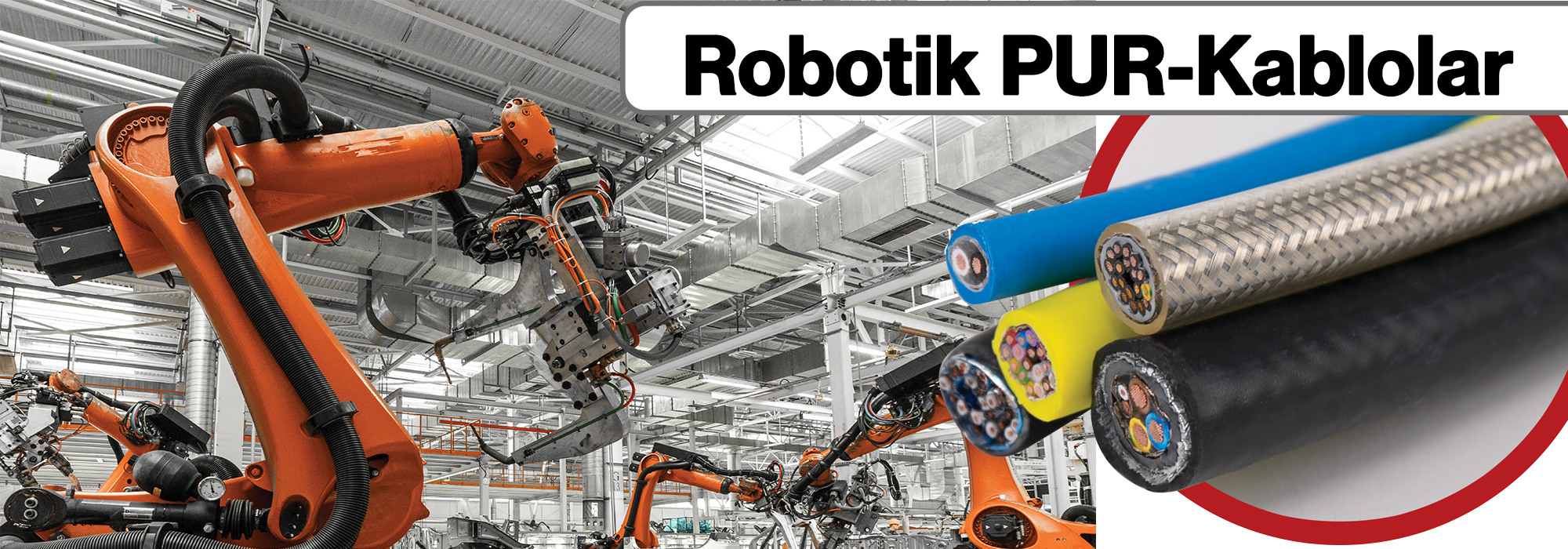

Endüstriyel Kablolar

Endüstriyel Kablolar, fabrika ve tesislerdeki elektrik ve iletişim altyapısını güçlendirmek için tasarlanmış özelleştirilmiş kablo sistemleridir. Baran Kablo, endüstriyel çözümler için yüksek kaliteli ve dayanıklı kablo ürünleri sunar.

Tekstil Örgülü Kablolar

Tekstil Örgülü Kablolar, yüksek dayanıklılık ve esneklikleri sayesinde elektronik cihazların korunmasına yardımcı olurlar. Ayrıca estetik bir görünüme sahip oldukları için de sıklıkla tasarım amaçlı kullanılırlar.